Friday, August 15, 2008

Hybrid Car Battery

The energy saving features come from the dual powered capabilities that are provided through the use of a gas powered automotive engine that is supplemented with power from an electrical motor and heavy-duty battery. The hybrid car battery further simplifies the Hybrid car functionality by continually providing free power to the electrical motor. The hybrid car battery utilizes such non-essential actions such as coasting and deceleration to recapture energy that would have otherwise been lost during the daily operation of the hybrid automobile.

To recapture energy in this fashion a term of regenerative braking is used. Should the battery require power, it has the ability to reap recharging benefits from the gas powered engine as well as the electrical motor that all fit under the hood of the recently introduced models of hybrid dual-powered automobiles. There is a myth that a hybrid battery offers the capability of simple plugs that can use household current to recharge. This myth has been dispelled by the fact that the recharging aspects are continually covered with the recharging actions of the gas powered engine and electrical motor so there will never be a time where this type of plug in device would be needed.

The specific charging abilities that are done to a hybrid car battery depend on the specific hybrid car model that is being driven. The braking and coasting recharge process is ample to fill every need that a hybrid car battery might require. With these gas-electric hybrids, true fuel savings can be recognized through the control panel on the dashboard that will provide the gas consumption, and active charging practices of the gas powered engine in relation to the hybrid car battery, with spikes in power showing when the electrical motor engages and supplies an additional power source when passing vehicles on the highway or wherever the need for additional power to propel the vehicle will be necessary to continue travel down the roadway.

The battery pack that is provided in a hybrid automobile is made up of many individual cells, and if one of them malfunctions, it will be necessary to replace the entire pack, instead of reenergizing the cell that has malfunctioned. The cost to replace a hybrid battery pack is substantial and has been know to cost anywhere from $2000 to $3000 apiece.

There are car manufacturers that provide additional coverage on the battery pack in a hybrid automobile. Considering the cost to replace without this coverage, any help would be beneficial and very much appreciated by the consumer. While this coverage will not pay the entire cost of replacing the hybrid battery, these dealerships are willing to pay for half of the cost that the consumer is charged to replace the battery pack. The failure instances in hybrid car batteries is quite rare and this is probably why such dealership offer this type of coverage. If the consumer avoids overcharging the battery, or draining it through the use of many automobile accessories, the life of the battery will meet up to the manufacturers expected life cycle as planned. Should the battery meet with failure before the expiration of the warranty period, the battery will be replaced free of charge by the battery manufacturer.

Monday, July 02, 2007

Ethanol - Overview

Where Does Ethanol Come From?

Ethanol comes from one of these three raw material groups:

- starchy crops, such as corn

- sugary crop, like fruit or sugarcane

- cellulosic plants, such as trees or wild grasses

- While the process for making ethanol varies somewhat depending on the feedstock, the basic steps are the same.

- The feedstock is milled or crushed, and may be treated with chemicals or enzymes. This step is designed to yield as much fermentable sugar as possible from the feedstock.

- Yeast is added to the prepared feedstock and sugars are converted to alcohol.

- The alcohol is extracted from the mixture by boiling it in a distiller.

Nearly all the ethanol made in the United States uses corn for a feedstock. Brazil, the world’s largest ethanol producer, makes ethanol from sugarcane. Other countries, such as France, use sugar beets and wheat as their primary feedstocks. With current technology, it is easiest and most efficient to produce ethanol from sugar crops, since the sugars in these feedstocks are readily available for fermentation. In the future, advances in ethanol production may increase yields and decrease the cost of producing ethanol from cellulosic material.

The Blends

Most likely, you're using ethanol in your car without even knowing it. In many regions, small amounts of ethanol are blended with gasoline to reduce emissions. Mixtures as high as E10 (10 percent ethanol and 90 percent gasoline) are safe for use in most vehicles, including hybrid models such as the Toyota Prius and Honda Civic Hybrid.

Much of the news lately has been about fuel blends that have higher ethanol content. The most common is E85 (85 percent ethanol and 15 percent gasoline), which only can be used in vehicles that are designed for that fuel. Currently, no hybrid models accept E85 fuel, but more than 20 E85-compatible cars and trucks (called “flexible-fuel vehicles”) are available now from four major manufacturers.

from Hybridcars.com

Saturday, June 02, 2007

How Electric Vehicles Work

The Power of the Gas Pump, By the Numbers

It doesn't take much to spark a conversation with an electric car advocate. A casual comment about the drawbacks of an EV - doesn't it take a long time to recharge? - will quickly spin into passionate arguments about efficiency, kilowatt-hours and states of charge. Electric car detractors are no less vociferous about the superiority of petro-power. Why do folks from both sides of the argument usually fail to win new converts? Because laypeople are clueless about even the most basic technical terms that underpin the discussion. So here comes my attempt to translate EV geek speak into English.

Power to the People

The first important issue to address is the fundamental difference between energy and power. There's a difference? There is - and if you can't readily tell the difference between the two, don't feel bad. Experts, officials and the media frequently confuse these terms. The difference between energy and power is quite simple:

- Energy is the ability to do work

- Power is the rate at which work is done

Understanding the difference is very important to the overall understanding of electricity and electrical systems, including electric cars and hybrid vehicles. The amount of energy in your batteries (or in your gas tank, for that matter) indicates the distance you can travel before refueling. That's known as range, and it's perhaps the most important issue involved in getting more electric cars on the road. The power rating of your electric motor (or gas engine) tells you how quickly you can turn that energy into useful work, such as vehicle acceleration.

To make this more useful in comparing gas-engine cars and electric vehicles, we need to introduce two more terms:

- kilowatt (a measure of power, abbreviated kW)

- kilowatt-hour (a measure of energy, abbreviated kW-hr or kWh)

Let's begin by flipping on a 100-watt light bulb - better yet, make that 10 of those 100-watt light bulbs. With all 10 bulbs illuminated, you are burning 1 kilowatt of power. Leave those light on for an hour, and you will have used 1 kilowatt-hour of energy. Get it?

In general terms, that same amount of energy - 1 kilowatt-hour - will move an electric car about four miles down the road. The amount of electric fuel that an EV driver can store in batteries depends on a lot of factors: the number and size/shape of batteries, and how willing you are to fully charge and discharge those batteries (thus affecting how long the batteries last). Those are all energy issues. The power issues, on the other hand, are more circumscribed: recharging your batteries from a common household outlet occurs at 1.5 kilowatts. Without getting into complicated math, just know that 1.5 kilowatts is a relatively small power spigot and it's going to take the driver of an EV a good few of hours, if not seven or eight, to recharge batteries capable of a couple hundred miles of driving. (To be more specific: At 4 miles range per kWh, one can charge from an ordinary wall outlet at a rate of, at most, 6 miles of added range per hour of charging, or "6 mph." Then there is the taper-off toward the end of charge, making the last 10-20% of charge even longer.)

On the other hand, an internal combustion engine stores its energy in the form of gasoline - and gas packs a 33 kilowatt-hour punch in every gallon. There's a lot of juice in that juice. Unfortunately, the tank-to-wheels efficiency of the gas engine is five or six times less than that of an electric motor's battery-to-wheels efficiency. If you consider what it took to extract the petroleum from the well, transport it to a refinery in supertankers and big rigs (both of which are also burning fossil fuels), and then inefficiently burn it in internal combustion engines, then the wastefulness looks even more extreme. (And that's without calculating the geopolitical and environmental effects of that oil supply chain.)

But for the moment, I'm not concerned about efficiency or sea otters. I need to get to work, my car is running nearly empty, and I need to quickly fill up on those "33 kilowatt-hour" gallons - or my boss will not be happy. Let's assume that my car's gasoline tank is 10 gallons. In the five minutes it took to fill up, I would have placed 330 kilowatt-hours of energy in my tank.

If I tried to get the same amount of energy from a household outlet, it would take me about nine days. Of course, it doesn't take nine days to recharge an EV, because the efficiency of an EV allows the driver to put less energy in the "tank" and still receive an adequate charge. But the comparison shows how gasoline became such a popular fuel over the past century: it allows us to put a lot of energy in our cars very quickly.

For the sake of comparing refueling times of gas and electric cars, we need to look at power - again the rate of transferring energy or, in this case, refueling. So, in power terms, I refuel my gas-powered car at 10 gallons per five minutes or 120 gallons per hour. Those 120 gallons - at 33 kilowatt-hours in a gallon - put 3,960 kilowatt-hours in my tank.

If I haven't lost you entirely, we can at last calculate the power of the gas pump:

- 3,960 kilowatt-hours per hour, or 3,960 kilowatts

If I did lose you, that's OK. We have the numbers necessary to compare the power of the gas pump versus the power of the electric cord.

- The power of the gas pump is 3,960 kilowatts

- The power of the electric cord is 1.5 kilowatts

- The gas pump is 2,640 times more powerful than the electric cord

Yes, I've disregarded the greater efficiency of the EV versus the gas engine when the fuel is used. But you get the point.

The next equation to consider is cost, but it doesn't involve another math lesson. The more important equation is not fundamentally mathematical: are we willing forgo the five-minute fillup in exchange for the overnight recharge if it helps us break the 100-year-old dominance of the internal combustion engine, and avert future oil price shocks, oil wars, and global warming? That's your homework assignment.

more in hybridcars.com

Friday, May 04, 2007

EPA invents battery-less hybrid system

By Peter Valdes-Dapena, CNNMoney.com staff writer.

NEW YORK (CNN/Money) - The Environmental Protection Agency says it can help drivers save fuel. It has said that for a long time, of course, but this time it's not talking about providing fuel mileage data for car shoppers. It's talking about a new invention created in its own Ann Arbor, Mich. research laboratories.

Called hydraulic hybrid technology, the system uses energy stored up during braking to help propel a vehicle during acceleration. The energy is stored in pressurized hydraulic fluid, the same sort of fluid used in brake lines and for power steering.

Ordinarily, when a driver applies the brakes in a car the energy removed from the vehicle's forward motion is simply lost as heat through the car's brake pads and rotors.

In gasoline-electric hybrids, like the Toyota Prius, some of that energy is recaptured through generators that charge batteries that, in turn, can help provide supplementary power to the vehicle.

In the EPA's hydraulic hybrid system, braking pressure is used to power pumps that compress hydraulic fluid. This stores energy in the same way you would if you squeezed a spring with your hands. When needed, the pressure is released and the expanding hydraulic fluid is used to power gears that help turn the vehicle's wheels.

Also, just as a gasoline-electric hybrid's gas engine can charge the batteries directly during highway cruising, the hydraulic hybrid's engine can also pump up the pressurized fluid tanks as the vehicle drives.

The EPA holds about 20 patents for technology used in the new system, said Margo Oge, director of the EPA's office of transportation and air quality.

While the EPA labs in Ann Arbor, Mich., are better known for creating new fuel mileage and emissions tests and standards, in recent years the labs have also begun working on creating new technologies for cleaner and more fuel-efficient vehicles.

The EPA began working on the system about 10 years ago, said Oge, under a Clinton administration program to research clean energy technology.

Pros and cons

There is a major advantage to the EPA's new system and one major disadvantage, the agency said. The advantage is its simplicity and relatively low cost. The system would cost an estimated $600 to install on a mass-production basis, the agency estimates, compared to $3,000 to $6,000 for an electric hybrid system.

The disadvantage is the system's weight, the EPA says. According to a 2004 EPA report, a hydraulic hybrid SUV would weigh about 190 pounds more than a conventional SUV. That means the EPA's system is most applicable to trucks where the added weight would make a smaller overall difference, the agency said.

The added weight of the system is similar to the weight of an electric hybrid system, although the EPA itself cites weight as a disadvantage.

Like gasoline-electric hybrids, hydraulic hybrid vehicles would see greater fuel savings in stop-and-go city driving than in steady highway cruising.

While the system could pay for itself in as little as a year in a heavier vehicle like big four-wheel-drive SUV, it would take at least four years to pay for itself in a midsized car, according to the EPA's report.

Still, the EPA says, that's a shorter payback time than drivers of gasoline-electric hybrids will see.

The EPA's system was demonstrated at an engineering conference last year on a prototype Ford Expedition SUV and will be used next year in at least one UPS delivery truck next year.

The UPS truck could get as much a 70 percent increase in fuel efficiency in city routes, the EPA estimates, and the added cost of the trucks should be paid off in fuel savings in about 2.5 years.

All these vehicles are diesel powered. Diesel engines are inherently more fuel efficient, to begin with, than gasoline engines. The use of diesel also allows the EPA to show off "clean diesel" technology it has also developed in its laboratories.

The system is currently being developed in partnership with International Truck and Engine Corp., Eaton Hydraulics, Parker Hannifin Corp., which specializes in making hydraulic controls, and the U.S. Army.

Friday, October 06, 2006

Car that runs on compressed air

A Korean company has created a car engine that runs on air.

The engine, which powers a pneumatic-hybrid electric vehicle (PHEV), works alongside an electric motor to create the power source.

(Picture Right: The pneumatic electrical hybrid vehicle (PHEV) runs on compressed air.)

The system eliminates the need for fuel, making the PHEV pollution-free.

Cheol-Seung Cho, of Energine Corporation, told CNN the system is controlled by a computer inside the car, which instructs the compressed-air engine and electric motor what to do.

The compressed air drives the pistons, which turn the vehicle's wheels.

The air is compressed using a small motor, powered by a 48-volt battery, which powers both the air compressor and the electric motor.

Once compressed, the air is stored in a tank, Cho said.

"The compressed air is used when the car needs a lot of energy, such as for starting up the car and acceleration. The electric motor comes to life once the car has gained normal cruising speed."

He said the system was relatively simple to manufacture and could be easily adapted to any conventional engine system.

"You could say our car has two hearts pumping. That is, we have separate motors running at different times, both at the time when they can perform most efficiently."

Cho also said the system could reduce the cost of vehicle production by about 20 percent, because there was no need to build a cooling system, fuel tank, spark plugs or silencers.

Cho hoped to see PHEVs on streets in the near future.

Peter Kemp, editor of "Petroleum Intelligence Weekly," told CNN that one of the biggest challenges for the invention was persuading the general public to embrace it.

"For this invention to take off, you'd need to get the backing of a major manufacturer. The major manufacturers that are looking at hybrid motors at the moment are looking at fuel cells -- battery with a gasoline diesel combination," he said.

Kemp said Toyota, which has released a hybrid car, had sold about 150,000 of the environmentally friendly model worldwide.

"But that is over several years. There is a lot of demand for that car but that is the only one that is really available and nobody knows whether Toyota is making any money out of it."

from CNN

Friday, August 04, 2006

Hybrid cars are so last century

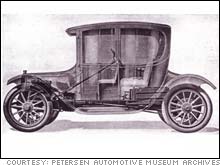

(Picture right: Diagram of the 1917 Woods Dual Power)

"Experimentation and discovery of new technologies is what really drives the auto industry and a walk through this exhibit is an entertaining trip from the past into our future beyond petroleum," said Dick Messer, director of the museum, in a statement.

Electric cars, clean and quiet but slow, were popular with the more practical-minded. They were seen as women's cars, appropriate for running errands around town.

Even after gasoline engines had improved enough to gain wide acceptance, engineers kept up experiments with other types of power. The 1938 Citroen 11 in the Petersen exhibit was fitted with a coal gas generator so that it could be driven despite World War II gasoline shortages in Europe. The fender-mounted generator produced a combustible gas by partially burning wood or coal.

Turbine cars used small jet engines to spin turbines that, in turn, powered the cars' wheels. One of the great promises of turbine power was that jet engines could run on a variety of different fuels including gasoline, diesel and kerosene.

"Chrysler, in the years right after World War II, was very serious about trying to make the gas turbine practical and economically viable," said Bob Casey, transportation curator for the Henry Ford Museum and Greenfield Village.

At the time, Chrysler's plan was to produce 500 turbine-powered 1966 Dodge Chargers that would be sold to the public, said Todd Lassa who wrote about the turbine cars for the current issue of Motor Trend Classic magazine. Those cars never appeared.

Ultimately, decades of turbine car experimentation led nowhere. They got no better fuel mileage than traditional gasoline engines and they had trouble meeting new emissions requirements, Lassa said.

Car companies have, most recently, turned to hydrogen as a promising "fuel of the future." In a move reminiscent of Chrysler giving turbine cars to American families, Honda has put its hydrogen fuel cell-powered FCX, one of which is in the exhibit, in the hands of real customers. Other companies have fuel cell-powered trucks in fleet use.

The fate of hydrogen fuel cells remains to be seen as more attention is given to the problem of extracting the hydrogen from sources such as hydrocarbon fuels.

"Engineering is not an easy business because for every advantage you have to look at disadvantages with the technology," said Lassa.

Friday, March 10, 2006

Why Hybrid?

by Julia Layton and Karim Nice

You might wonder why anyone would build such a complicated machine when most people are perfectly happy with their gasoline-powered cars. The reason is twofold: to reduce tailpipe emissions and to improve mileage. These goals are actually tightly interwoven.

Let's take the example of the California emissions standards, which dictate how much of each type of pollution a car is allowed to emit in California. The amount is usually specified in grams per mile (g/mi). For example, the low emissions vehicle (LEV) standard allows 3.4 g/mi of carbon monoxide. The key thing here is that the amount of pollution allowed does not depend on the mileage your car gets. But a car that burns twice as much gas to go a mile will generate approximately twice as much pollution. That pollution will have to be removed by the emissions control equipment on the car. So decreasing the fuel consumption of the car is one of the surest ways to decrease emissions.

Carbon dioxide (CO2) is another type of pollution a car produces. The U.S. government does not regulate it, but scientists suspect that it contributes to global warming. Since it is not regulated, a car has no devices for removing CO2 from the exhaust. A car that burns twice as much gas adds twice as much CO2 to the atmosphere.

Auto makers in the United States have another strong incentive to improve mileage. They are required by law to meet Corporate Average Fuel Economy (CAFE) standards. The current standards require that the average mileage of all the new cars sold by an auto maker should be 27.5 mpg (8.55 liters per 100 km). This means that if an auto maker sells one hybrid car that gets 60 mpg (3.92 liters per 100 km), it can then sell four big, expensive luxury cars that only get 20 mpg (11.76 liters per 100 km)

You can actually take steps to drive your car in ways that increase its gas mileage. In the next section, we'll look at some tips for increasing the efficiency of your hybrid (or just gas-powered) car.

More Power, Less Efficiency

A driver's desire for quick acceleration causes our cars to be much less efficient than they could be. You may have noticed that a car with a less powerful engine gets better gas mileage than an identical car with a more powerful engine. Just look at the window stickers on new cars at a dealership for a city and highway mpg comparison.

The amazing thing is that most of what we require a car to do uses only a small percentage of its horsepower. When you are driving along the freeway at 60 mph (96.6 kph), your car engine has to provide the power to do three things:

- Overcome the aerodynamic drag caused by pushing the car through the air.

- Overcome all of the friction in the car's components such as the tires, transmission, axles and brakes.

- Provide power for accessories like air conditioning, power steering and headlights.

For most cars, doing all this requires less than 20 horsepower. So, why do you need a car with 200 horsepower? So you can "floor it," which is the only time you use all that power. The rest of the time, you use considerably less power than you have available.